Stop letting downtime drain your profits and disrupt your delivery schedule. Rolon Mobile Truck Repair brings the full capabilities of a repair shop directly to your location, eliminating the need for expensive tows and long wait times at a garage. From advanced diesel diagnostics and air system leaks to reefer unit repairs, our technicians provide expert on-site truck repair near me to get your wheels turning fast.

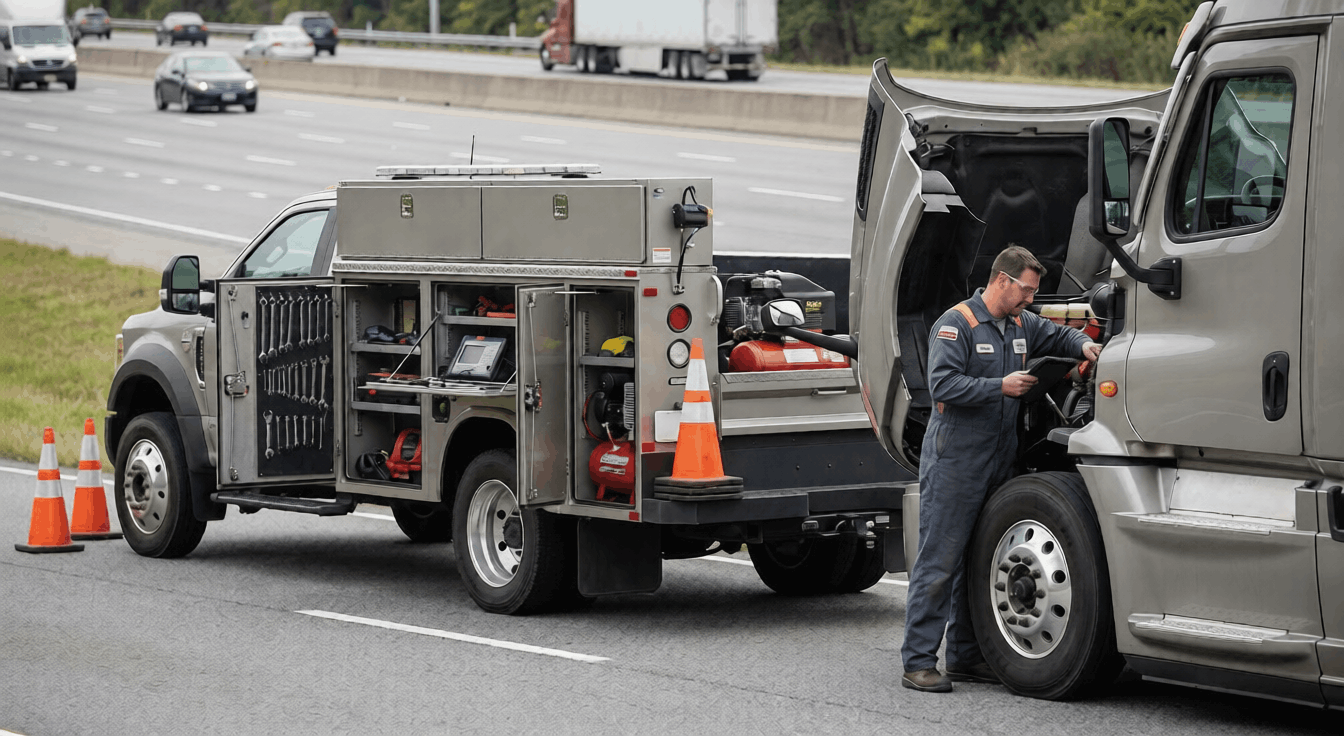

You’ve seen it on the highway: a massive 18-wheeler on the shoulder, its hazards flashing. Your first thought is often about the potential traffic jam, but have you ever wondered what actually happens next? For many drivers, the answer isn’t a giant tow truck—it’s a high-tech, house-call solution arriving to solve the problem right there on the pavement.

For decades, the standard response when a truck broke down on the highway involved a complex and costly tow to a distant repair shop. This process could sideline a vehicle for hours or even days. Every hour a truck sits idle represents significant lost revenue for its operator, not to mention the downstream effects on delivery schedules. This expensive delay, known as downtime, has long been one of the biggest challenges in the trucking industry.

Today, a more efficient answer is changing the equation: on-site truck repair. Think of it like a doctor making a house call, but for an 80,000-pound machine. Instead of moving the patient, a specialized mechanic arrives in a fully equipped service vehicle—a workshop on wheels—to provide emergency roadside truck assistance. This modern approach gets drivers back on the road faster, saving time, money, and keeping the supply chain moving.

The "Doctor's House Call" for a 40-Ton Vehicle: What is Mobile Truck Repair?

When a commercial truck breaks down, the solution isn’t always a massive tow. Instead, think of it like a doctor making a house call for a 40-ton patient. On-site truck repair sends a specialized mechanic in a mobile workshop directly to the stranded vehicle, ready to fix the problem right there on the shoulder of the road. It’s a service designed to handle common issues without ever moving the truck to a garage.

The entire purpose of this service is speed. For a trucking company, every minute a truck sits idle is money lost and a delivery falling further behind schedule. Bringing the repair to the truck means a technician can often get the vehicle running in a fraction of the time it would take to arrange a tow, drive to a facility, and wait in line at a busy shop.

This isn't about fixing a bigger version of your family car. A real guide to choosing a mobile mechanic must emphasize its focus on commercial vehicles with unique systems like air brakes and powerful diesel engines. This specialized field, often called mobile diesel repair, is about turning a potentially catastrophic delay into a manageable roadside stop.

The High Cost of the Hook: Mobile Repair vs. Towing to a Shop

When a truck is stranded, the dispatcher faces a crucial choice: call for a tow or a mobile mechanic? While towing seems like a familiar solution, the decision of mobile truck repair vs. towing to a shop is a serious financial calculation. For the trucking industry, the cheapest option isn’t always the one with the lowest upfront price tag; it's the one that gets the wheels turning again the fastest.

The key difference is a concept called "downtime." Imagine a breakdown at 10 AM. A mobile mechanic might arrive by 11 AM and have the truck fixed and back on the road by 1 PM—a total of three hours of downtime. In contrast, waiting for a tow, getting hauled to a shop, and then waiting for an available mechanic can easily turn that same breakdown into an all-day ordeal, stretching downtime to eight hours or more.

This time difference has a direct impact on cost. While people often wonder how much a mobile truck mechanic costs, the real expense is lost revenue. A truck that isn't moving isn't earning. Those extra five hours spent waiting for a shop repair can cost a company hundreds or even thousands of dollars in missed delivery payments. This is a constant concern for anyone managing commercial vehicle fleet maintenance, making the efficient on-site repair the more economical choice.

Beyond the immediate financial loss, extended downtime causes ripple effects, from delayed store shipments to potentially spoiled cargo. Choosing the faster repair prevents these larger disruptions. But this speedy solution is only practical if the mechanic can actually fix the problem on the spot. Fortunately, these mobile workshops are equipped to handle far more than just a dead battery.

More Than Just a Flat Tire: The Surprising Range of Roadside Truck Repairs

While it’s easy to imagine a roadside fix involving a simple jump-start or a new tire, the reality is far more advanced. A well-equipped mobile technician can tackle a huge percentage of the most common semi truck breakdown causes, preventing a long and expensive trip to a repair shop. These mechanics are trained to diagnose and resolve complex system failures right on the shoulder of the road.

The problems they face are often more intricate versions of car trouble, requiring specialized knowledge and tools. A 24/7 heavy-duty truck service can typically handle issues like:

-

Air System Leaks: Unlike cars, heavy trucks use compressed air to operate their brakes and suspension. A leak can disable the vehicle, and finding and fixing it is a top priority.

-

Electrical Problems: From replacing powerful commercial-grade batteries to tracing faults in complex wiring and sensor systems, electrical work is a frequent need.

-

Fuel Delivery Issues: A clogged fuel filter or a failed fuel pump can stop a multi-ton truck in its tracks. Technicians can replace these components to get fuel flowing again.

What truly separates modern mobile repair is the high-tech diagnostic process. Today’s semi-trucks are rolling computers, and a technician will often start by plugging a laptop directly into the engine’s electronic control module. This allows them to perform sophisticated roadside diesel engine diagnostics, reading error codes and analyzing real-time data to pinpoint the exact cause of a problem, much like a doctor running a scan to find an injury.

Performing these advanced mechanical and digital repairs miles from any garage requires more than just skill—it demands a unique set of equipment. To accomplish this, the mechanic's truck isn't just a mode of transport; it's a complete, self-contained workshop on wheels.

A Repair Shop on Wheels: The Specialized Gear Inside a Mobile Service Truck

To make these roadside miracles happen, the mechanic's service truck is packed with far more than a standard toolbox. It’s a self-sufficient powerhouse, often equipped with its own industrial-grade air compressor to power tools and reinflate massive tires. Many are also outfitted with welding equipment for repairing cracked metal brackets and frames on the spot. This heavy-duty gear allows a technician to perform tasks that would otherwise require a fully equipped garage, turning a highway shoulder into a functional, if temporary, repair bay.

A crucial element for effective on-site truck repair is a carefully curated inventory of parts. Instead of carrying everything, a skilled mobile semi-truck mechanic stocks their vehicle with the most common failure items—belts, hoses, sensors, and filters known to cause the majority of breakdowns. This strategic "go-bag" of parts is based on experience and data, ensuring the technician has the right component on hand to solve the problem without making a trip to a parts store.

Ultimately, this combination of advanced tools and a rolling parts warehouse is what makes emergency roadside truck assistance so effective. The vehicle provides the capability, but it’s the technician's expertise that allows them to diagnose the issue, pull the right part from a drawer, and use the right tool to get a driver back on their journey. Their skill isn't limited to what’s under the hood, either; their expertise often extends to the entire rig.

Beyond the Engine: Fixing Trailers, Refrigerated Units, and Liftgates

A truck’s journey can be stopped by more than just engine trouble. The massive trailer it pulls is a vehicle in its own right, with its own set of potential problems. Technicians are often called out to fix issues with the trailer’s frame, its complex air brake system, or the "landing gear"—the legs that support the trailer when it’s unhitched. A problem with any of these can make the entire rig unsafe or impossible to move, even if the truck itself is running perfectly.

The stakes get even higher when the trailer is refrigerated. These special trailers, often called "reefers," are essentially giant, rolling refrigerators responsible for keeping everything from ice cream to life-saving medicines at a precise temperature. If a reefer unit fails, the clock starts ticking immediately. A quick response for trailer and reefer repair services can be the only thing standing between a successful delivery and thousands of dollars in spoiled cargo, making these some of the most urgent calls a mobile mechanic receives.

Beyond urgent breakdowns, technicians also handle critical safety issues. A burnt-out trailer light or a worn tire can fail a roadside safety check, so mobile mechanics provide on-the-spot DOT inspection repair services to get trucks compliant and rolling again. This work is a form of preventative maintenance for commercial trucks, catching small problems before they cause a major delay or an accident. It’s this broad expertise, covering everything from the engine to the last taillight, that truly makes these technicians essential.

The Unseen Heroes Keeping Your World in Motion

Before, a stalled 18-wheeler on the highway might have been just a roadblock. Now, you can see the invisible crisis unfolding—the financial drain of downtime and the race to get a critical asset moving again. You understand that effective commercial vehicle fleet maintenance isn't about towing a problem away, but about solving it with the speed and precision of on-site truck repair.

This service is the unsung hero of the modern supply chain. The timely arrival of your packages, the fresh food in your grocery store, and the fuel at the gas station all depend on a logistics network that cannot afford to stop. These mobile mechanics are the first responders who prevent small delays from becoming major disruptions, protecting the flow of goods we all rely on.

The next time you pass a service truck working on the shoulder, you’ll no longer see just a traffic delay. You’ll see the economy in action—a skilled professional keeping the promises of our interconnected world.