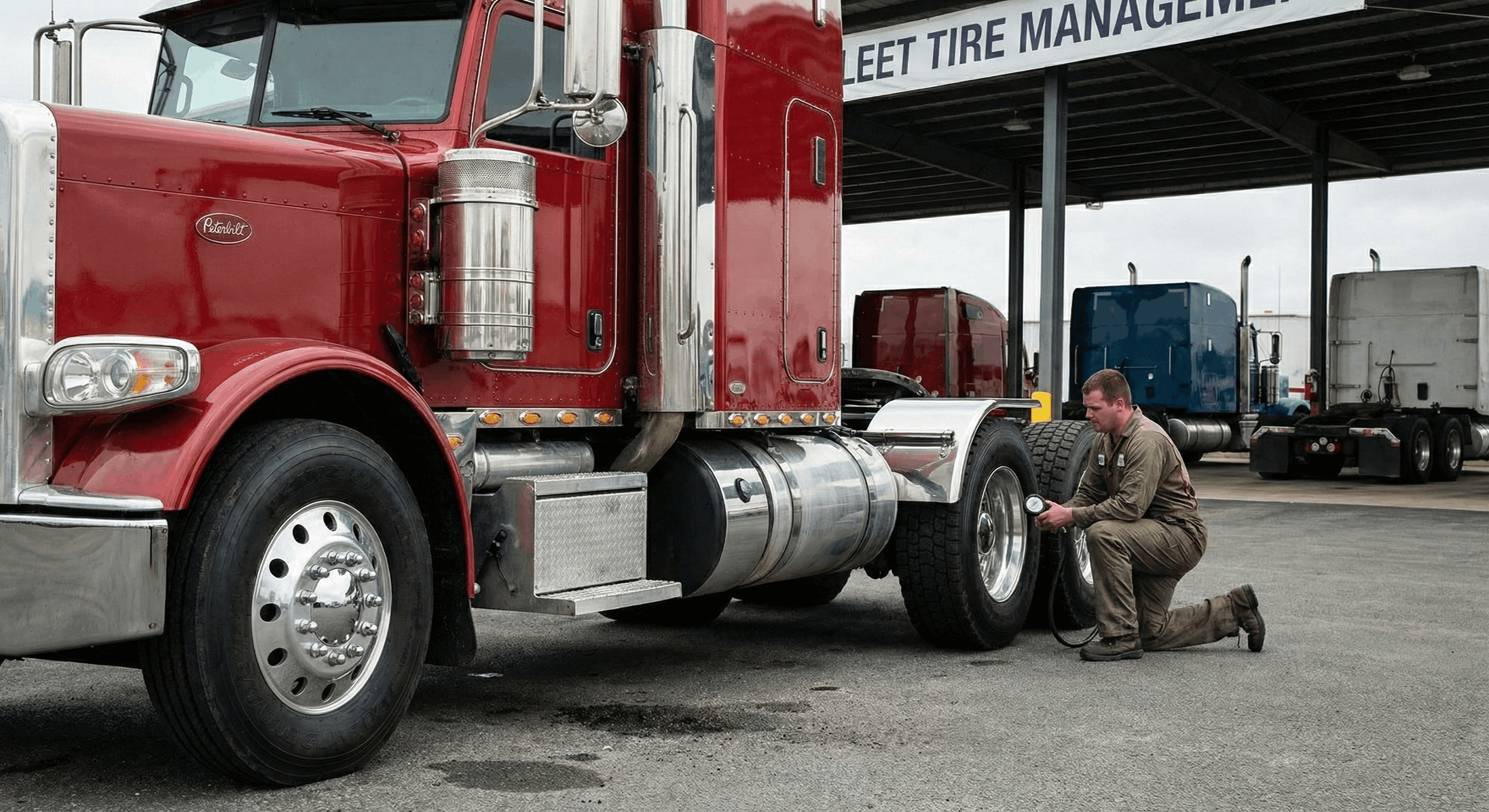

Don’t let a flat tire or low PSI lead to a dangerous blowout and costly downtime. Rolon Mobile Truck Repair provides fast, on-site commercial truck tire service for semi-trucks and trailers, handling everything from emergency patching to full replacements. We bring expert solutions directly to your location to keep your fleet safe and moving. Contact us now for reliable mobile tire assistance in Sanford, FL and the surrounding areas!

The next time you’re on the highway, glance at the tires on a passing semi-truck. They seem big, but the reality is staggering. A single one of these big truck tires stands nearly four feet tall and can weigh over 100 pounds. What's even more surprising is the truck tire cost; industry data shows a brand-new tire can easily top $500.

Now, multiply that by eighteen. If your family car manages just fine on four tires, why do semi-truck wheels number in the double digits? It’s a common question on long road trips, and the answer has nothing to do with speed or style. It’s a story of immense weight, extreme heat, and crucial economics. The design reveals a hidden world of clever engineering that manages immense forces and is essential to both highway safety and the entire economy.

The Snowshoe Secret: Why Trucks Need So Many Wheels

If your car manages just fine on four tires, why does a big rig need 18? The answer isn't about traction or speed, but about spreading an enormous burden. A fully loaded semi-truck can legally weigh up to 80,000 pounds—the equivalent of about 20 family cars. Putting all that weight on just four tires would be like trying to walk across soft mud in high heels; you’d sink right in. The extra wheels act like snowshoes, distributing the immense load over a much wider surface area.

This principle of weight distribution is the key to protecting our roads. By using many tires, especially in side-by-side pairs known as “duals,” the pressure on any single spot of asphalt is dramatically reduced. This prevents the truck from carving ruts into the pavement and causing costly damage. Without this clever spread, our highways would quickly crumble under the constant stress of modern shipping.

So where does the magic number 18 come from? The configuration is surprisingly consistent. The tractor (the front part with the engine) has 10 wheels: two single tires up front for steering and eight drive tires in the back, arranged in four dual pairs. The trailer it pulls typically carries another eight wheels, also as four dual pairs. That simple math—10 on the tractor plus 8 on the trailer—gives us the classic “18-wheeler” that keeps our economy rolling.

The Tire Team: Why Not All Truck Tires Are Created Equal

While all 18 tires share the immense load, they don’t all have the same job. Think of them less as identical copies and more like a specialized sports team, with each position designed for a specific task. Commercial truck tires are divided into three main roles: steering, driving, and simply carrying the trailer’s weight. This division of labor is crucial for safety and efficiency.

Up front are the two steer tires, which are the captain and navigator of the team. Their most important job is to respond precisely to the driver’s commands. To do this, their tread pattern usually features straight, continuous ribs. These ribs act like rudders, helping the truck track straight and providing stability while shedding water to prevent hydroplaning.

In contrast, the eight drive tires behind the cab are the powerhouse. They are responsible for turning the engine’s power into forward motion. To get the best grip, their tread pattern is much more aggressive, with deep, blocky lugs. This design is similar to the tread on a good pair of hiking boots, built to dig in and provide powerful traction for pushing the truck’s massive weight.

This teamwork approach means every tire is an expert at its position. The remaining trailer tires are built for durability and low rolling resistance, as their main job is to carry the load with as little friction as possible. With so many specialized—and expensive—tires, you can see why trucking companies look for clever ways to make them last.

The Secret to a 500,000-Mile Tire: What Are 'Retreads'?

With each tire costing hundreds of dollars, replacing all 18 on a semi-truck would be a monumental expense. This financial reality has led to an ingenious solution that gives a tire a second, third, or even fourth life. It’s a process called retreading, and it’s very similar to putting a new sole on a high-quality pair of boots. Instead of discarding the entire tire when the tread wears out, the strong inner structure is saved and reused.

The secret lies in the tire’s incredibly durable inner structure, known as the casing. This casing is built to last far longer than a single layer of tread. In the retreading process, the worn-out tread is buffed away, and a brand-new layer of tread is bonded to the original casing using heat and pressure. This can cut the cost of a replacement tire by more than 50% and allows a single casing to travel over 500,000 miles, making it an economic and environmental game-changer for the trucking industry.

This brings up the strips of rubber, or "gators," often seen on highway shoulders. Many people assume they are from failed retreads, but they are the result of tread separation. This is a catastrophic type of commercial tire failure where the tread layer rips away from the tire’s main body.

While it’s easy to blame retreads, the primary culprit for tread separation on any tire—new or retreaded—is usually something else: heat. Running a truck tire with low air pressure causes it to flex excessively, generating immense heat that can break down the bonds holding the tire together. So, that rubber on the road isn't a sign of a bad retread, but a dangerous sign of a tire that failed under pressure. The tire's casing holds the key to its lifespan, but the information printed on its side holds the key to its identity.

Decoding the Sidewall: Your Guide to a Tire's "Secret Language"

Every tire has a story to tell, and it’s written in a code of numbers and letters right on its sidewall. Learning how to read semi truck tire sidewall information reveals just how different they are from your car’s. While you’ll see a long string of characters like 295/75R22.5, the most telling detail is often the last number. That 22.5 represents the diameter of the wheel it fits, in inches. Compare that to the 16 or 17-inch wheels on a typical car, and you get an immediate sense of the massive scale involved.

Beyond just its size, the sidewall also reveals the tire’s brute strength. This is often indicated by a "Load Range" letter. Think of it as a simple strength grade; while a light truck or car tire might be a Load Range C or D, most heavy-duty truck tires are a Load Range G or H. The meaning is simple: a tire with a Load Range H rating has a much stronger internal construction, allowing it to hold higher air pressure and support the immense weight of a fully loaded trailer without failing.

This combination of massive size and incredible strength is what allows just 18 tires to support an 80,000-pound vehicle. The numbers explain what the tire is, but all of that robust engineering is completely dependent on one critical, invisible component. Without the correct, high pressure, even the strongest tire is a recipe for disaster.

The Power of Air: How Tire Pressure Affects Safety and Fuel Costs

That incredible strength built into the tire's structure would be useless without the right amount of air inside. While your car tire might be happy at around 35 pounds per square inch (PSI), a truck tire needs to be inflated to 100 PSI or more. This extreme pressure makes the tire incredibly stiff, enabling it to support thousands of pounds without squashing flat. Think of it as the difference between trying to stand on a slightly deflated air mattress versus a fully inflated one; only the firm, high-pressure surface can properly support the weight.

Beyond just fighting gravity, proper inflation also has a huge impact on fuel. An underinflated tire bulges at the bottom, creating a wider, mushier footprint on the road. This increases "rolling resistance," which is just a technical term for the effort needed to keep the tire moving. It’s like trying to ride a bicycle with half-flat tires—you have to pedal much harder to go the same speed. For a trucking company, that extra effort translates directly into burning more fuel, so one of the simplest ways to improve truck tire fuel economy is to maintain correct air pressure.

This extra effort isn't the only problem. As a low tire flexes and deforms with every rotation, it generates a dangerous amount of heat. You can feel this effect yourself by quickly bending a paperclip back and forth—it gets surprisingly hot. Now imagine that happening 500 times every mile at highway speeds. This intense heat buildup is the number one enemy of a truck tire, breaking down the rubber and leading to the catastrophic blowouts that leave shredded "gators" on the interstate.

Because the stakes are so high for both safety and efficiency, monitoring air pressure is a constant focus. Many modern trucks are even equipped with a commercial tire pressure monitoring system that alerts the driver to the slightest drop in pressure. It’s a simple concept that has a massive impact, turning invisible air into a truck’s most critical tool for staying safe and efficient on its long journey.

A System in Motion: What to Spot on Your Next Road Trip

A passing semi-truck is more than just a large vehicle; it's a complex system where every tire plays a distinct role. Each wheel tells a story of weight, heat, and efficiency—a rolling display of incredible forces and clever design.

On your next drive, notice the differences in the tires. Look for the ribbed tread on the front steer axle, which guides the truck, and contrast it with the blocky, deep-grooved drive tires that provide the power. Observe the dual-wheel setups that distribute the immense weight.

What was once just a truck with many wheels is now an example of specialized engineering in action, essential for keeping our economy moving safely and efficiently.