Every minute your rig is sidelined is money out of your pocket. Skip the expensive tow and long wait times at the shop with Rolon Mobile Truck Repair. We provide expert, on-site 24 hour truck repair near me, specializing in everything from air system leaks and electrical fixes to emergency tire replacements. Our technicians are ready to minimize your downtime and protect your HOS clock with fast, reliable service.

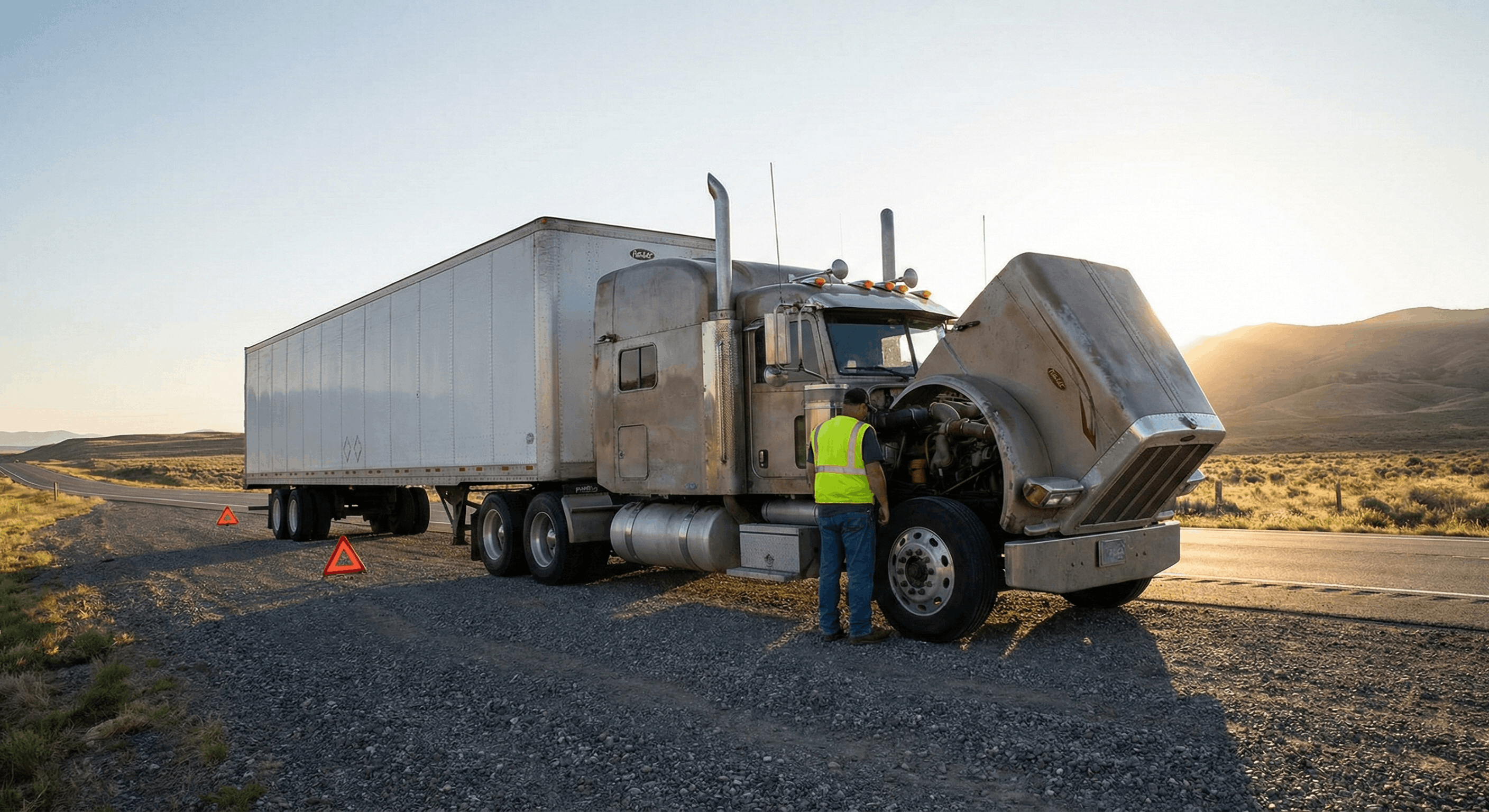

You’ve seen it before: a massive 18-wheeler on the highway shoulder, its hazards flashing. While it looks like a simple traffic annoyance, it’s actually a high-stakes emergency. Industry data reveals that every hour a truck is stopped can cost well over a hundred dollars in lost revenue and delayed schedules, turning a mechanical failure into a costly crisis.

For the driver, the question of what to do when your semi breaks down has an urgent answer. Instead of a slow tow to a distant shop, the solution is often a call for 24 hour truck repair—a mobile mechanic service that acts like a roadside emergency room for big rigs, arriving with the tools and parts to fix the problem on the spot.

Ultimately, this heavy duty truck breakdown assistance is the hidden system that keeps our lives on schedule. That rapid repair on the highway is what ensures the truckload of groceries, medicine, or online orders arrives on time, preventing a simple breakdown from causing a ripple effect that reaches your front door.

The Hidden Cost of a Breakdown: Why Every Minute Counts

When a truck stops unexpectedly, it’s not just an inconvenience—it’s a serious financial problem. A single commercial truck can earn hundreds of dollars in revenue every hour it’s on the road. A breakdown instantly turns that income into a loss, and the true emergency truck repair cost isn't just the mechanic's bill, but the thousands in lost earnings and potential late fees that quickly pile up.

Adding to the pressure, drivers are on a strict legal clock. Federal regulations known as Hours of Service (HOS) limit their daily driving time. A four-hour breakdown doesn't just delay a delivery; it can exhaust a driver’s available hours for the day, forcing a mandatory 10-hour stop just miles from their destination.

For some loads, the stakes are even higher. Consider a refrigerated trailer, known in the industry as a “reefer,” carrying temperature-sensitive goods like fresh produce or medicine. If its cooling unit fails or the truck is stranded in the summer heat, a delay of just a few hours can spoil the entire shipment, turning a simple repair into a total financial loss.

With lost revenue, a ticking legal clock, and precious cargo at risk, the pressure is immense. This is why a fast emergency roadside truck service is so critical. Getting a truck moving again in under two hours is a massive win compared to waiting a day for a tow, because on the highway, time truly is everything.

What’s Inside a Mobile Repair Truck? (Hint: It’s More Than a Toolbox)

When you see one of these specialized vehicles pull up, it’s best to think of it as a complete workshop on wheels, not just a service van. Unlike car-focused roadside assistance that might bring gas or a new battery, a mobile service truck is designed for serious on-site truck and trailer repair. Its entire purpose is to get an 80,000-pound machine moving again, often without needing a tow, making it a critical resource when a driver searches for a “mobile semi truck mechanic near me.”

Inside, you won’t just find wrenches and sockets. These trucks carry heavy-duty equipment that's essential for big rigs. A powerful, built-in air compressor is a must-have for diagnosing and repairing a truck’s air brake system—a frequent cause of breakdowns. Many also have an onboard welder, allowing the mechanic to literally fuse broken metal brackets or frame components right on the shoulder of the highway, a task impossible for a standard service vehicle.

This rolling arsenal is what makes the difference in the debate of mobile repair vs towing to a shop. Having the right tools on hand allows a skilled technician to perform complex repairs that would otherwise require a long and expensive trip to a garage. With this capability, a technician is ready to tackle many of the most frequent culprits that sideline a truck.

What Are the Most Common Culprits of a Roadside Breakdown?

While many people imagine a catastrophic engine failure, the most common semi truck breakdown causes are often less dramatic but just as disabling. A mobile mechanic providing roadside assistance for commercial vehicles is typically racing to fix a problem that has more to do with the supporting systems than the engine itself. These on-the-spot repairs are crucial for avoiding a tow and getting freight moving again.

Often, the issue is one of a few usual suspects. After a call comes in, the technician is likely preparing to handle:

-

Blown Tires or Wheel Issues: With 18 or more tires on a single rig, the odds of a failure are high.

-

Air System Leaks: This is a huge one, as it directly affects the brakes.

-

Electrical and Fuel Problems: From dead batteries to clogged fuel filters, these issues can stop a truck in its tracks.

That air system issue is particularly interesting because of how truck brakes are designed. Unlike your car, where you apply pressure to stop, a truck’s system uses constant air pressure to keep its powerful brakes released. If a leak develops and pressure is lost, the brakes automatically engage as a fail-safe. This is why a small, hissing air hose can render an 80,000-pound vehicle completely immobile, often requiring immediate repair.

Just as vital are the connections that join the truck to its trailer. You may have noticed the color-coded, palm-sized air-line connectors—known in the industry as gladhands—and the thick, coiled electrical cord called a pigtail. If either of these is damaged, the trailer loses its lights and brakes, creating a dangerous situation and a common target for DOT inspection failure repairs.

Mobile Repair vs. Towing to a Shop: How Does a Mechanic Decide?

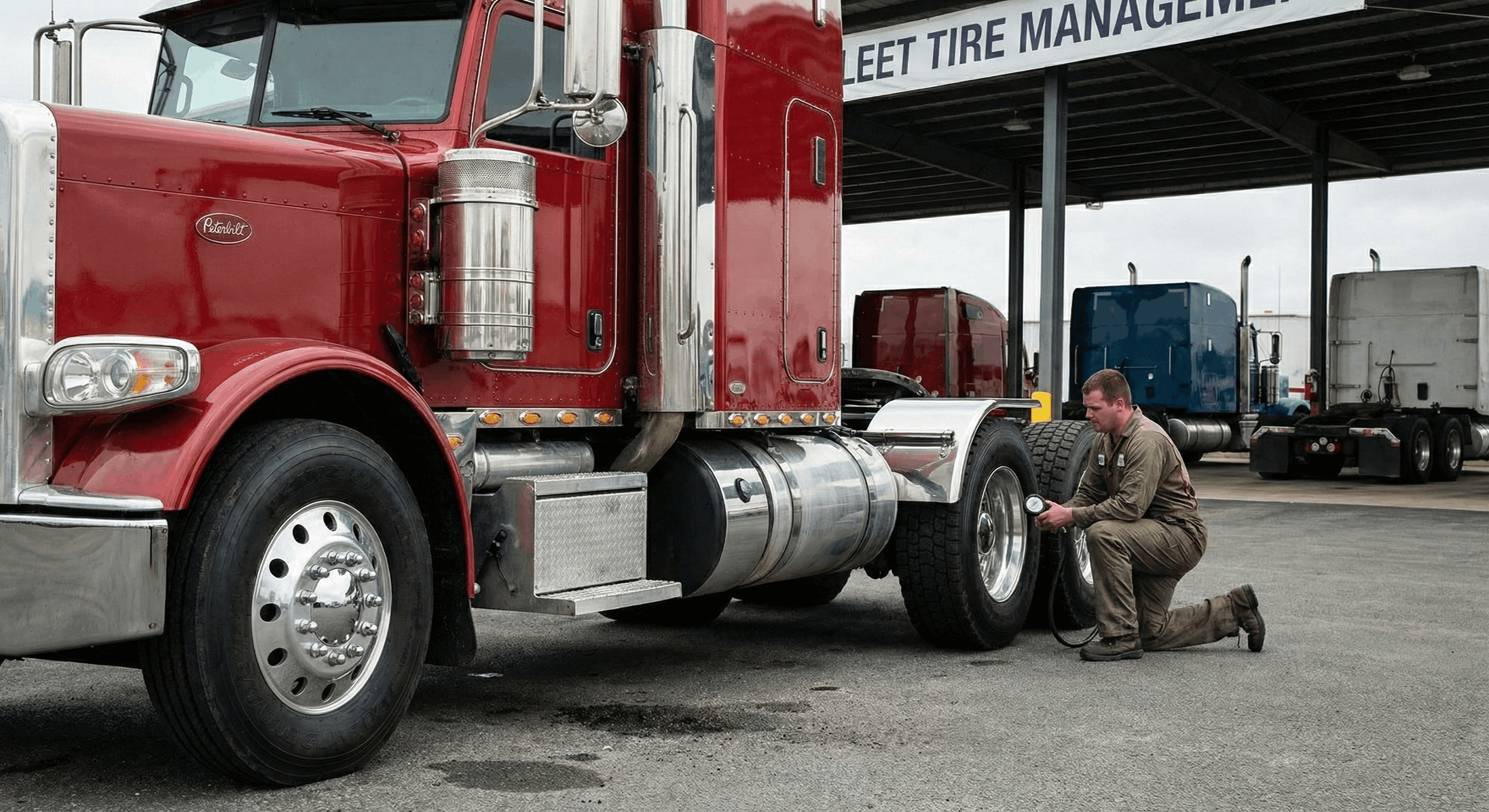

Once on scene, a mobile mechanic’s first job is to act like a roadside detective in a process called triage. They aren't just there to fix the part that broke; they need to quickly diagnose why it broke and determine the scope of the repair. Is this a simple fix that will get the truck rolling in an hour, or is it a symptom of a deeper problem? This quick, expert assessment is the most critical part of any heavy duty truck breakdown assistance, as it dictates the entire recovery plan.

Problems like a faulty alternator, a snapped belt, a leaky hose, or a dead battery are perfect candidates for on-the-spot mobile repair. These are generally accessible parts that a technician can replace using the tools on their service truck. However, if the issue is internal to the engine or transmission—think major oil leaks or grinding gears—it's a different story. A repair that requires lifting the entire cab or needs a specialized, multi-ton lift is out of scope for the roadside and must be towed to a shop.

Ultimately, the decision between mobile repair vs. towing to a shop comes down to safety, speed, and cost. A two-hour, on-site fix is vastly cheaper than the combined cost of a heavy-duty tow, shop labor, and days of lost revenue waiting for a repair bay to open up. This entire system, however, hinges on one crucial factor: finding a reliable mobile truck mechanic in the first place.

How Do You Find a Mechanic in the Middle of Nowhere?

When a truck breaks down, the driver rarely searches for help themselves. Their first call is typically to their fleet dispatcher—the logistics coordinator back at headquarters who acts as the mission control for dozens of trucks. This person immediately takes charge of the emergency, managing the response so the driver can focus on staying safe on the roadside. It’s this central coordination that transforms a chaotic situation into a structured process.

So how does a dispatcher in Ohio find a mechanic in rural Nevada? They use professional service directories. These nationwide networks are like a highly-vetted contact list, connecting fleets with trusted mobile repair shops across the country. This system takes the guesswork out of finding a reliable mobile truck mechanic, ensuring the person dispatched to the scene is a qualified and reputable professional, not just a random search result.

Even with these powerful tools, "near me" means something very different in the trucking world. In remote areas, the closest available mobile semi truck mechanic might be an hour or more away. This travel time is a crucial part of the nationwide emergency fleet service equation, and it’s just the first of several costs that start to add up once that service truck hits the road.

A Surprising Look at Emergency Repair Bills

A bill for several hundred dollars for a roadside fix can seem steep at first glance, but the price makes perfect sense when you break it down. An emergency repair invoice typically has three main components: a call-out fee, the cost of labor, and the price for parts. That initial call-out fee isn’t just for gas; it covers the mechanic’s travel time and the overhead of dispatching a rolling workshop packed with specialized tools to a remote location.

Then there’s the labor itself. Just like needing a plumber on a Sunday, after hours commercial truck service comes at a premium. A mechanic working at 2 a.m. will understandably have a higher hourly rate than one working on a Tuesday afternoon. This rate reflects the urgency and 24/7 availability that the entire on-site truck and trailer repair industry is built on.

When you see the whole picture, a $700 bill for a 90-minute air line repair suddenly looks like a bargain. Considering a single day of downtime can cost a trucking company thousands in lost revenue and late-fee penalties, that emergency repair is a smart investment. It’s the true answer to "how much does emergency truck repair cost?": far less than doing nothing at all.

The Unsung Heroes Keeping Your World Moving

That flashing light on the highway shoulder no longer signals just a delay. It represents an invisible clock ticking—a race to save perishable cargo, meet a critical deadline, and keep the supply chain intact. The speed and expertise of a 24 hour truck repair service is a vital economic function, not just a simple fix. Passing one of these roadside scenes feels different with this insight. You see beyond the disruption and recognize the skill involved, appreciating the challenge of servicing these massive commercial vehicles under pressure.

This hidden network of emergency roadside truck service is powered by unsung heroes, ensuring the products we all depend on arrive safely. It’s more than witnessing a breakdown; it’s watching a crucial link in our economy being repaired, one bolt at a time.